The world is moving very fast and many industries are innovating to compete by leveraging the power of an AI to automate their things, which creates major positive impacts to heighten their business.

Specially, manufacturing industries are using AI to automate their equipment or production process. Automation increases the production capacity & reduces costs, which results in great efficiency.

In this article, we will see how automation is transforming the complete structure of the manufacturing industry. To get proper understanding & knowledge, be conscious while reading the article.

Artificial Intelligence (AI) in manufacturing is revolutionizing how products are made, improving efficiency and safety through automation. AI uses smart algorithms and machine learning to manage production processes, monitor machinery, and ensure worker safety. This helps manufacturers optimize operations, reduce waste, and maintain higher product quality.

AI is used in various manufacturing functions, including automating repetitive tasks, monitoring equipment for predictive maintenance, ensuring compliance with safety regulations, and improving production speed. These systems provide real-time data analysis, allowing manufacturers to make instant adjustments and optimize their processes

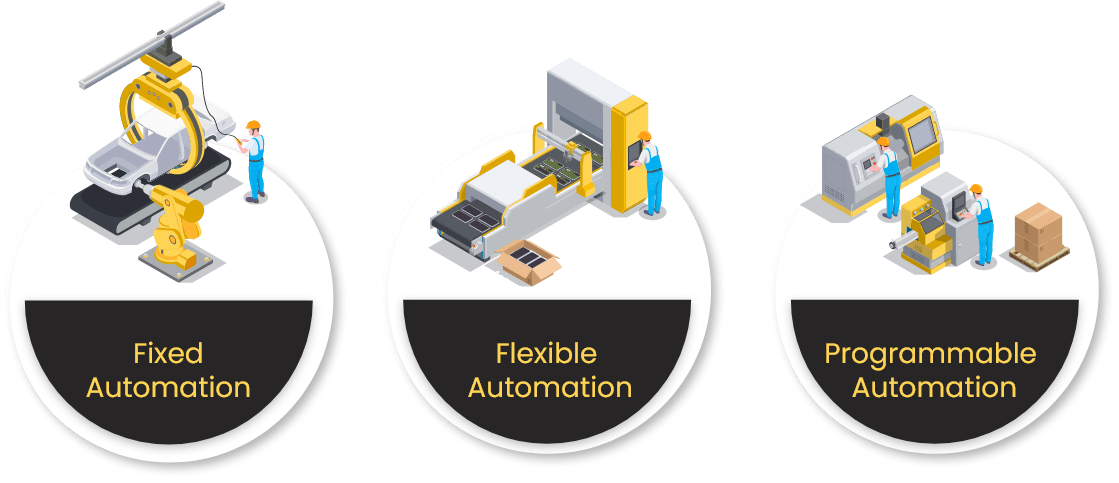

Basically, there are 3 types of manufacturing automation that are being used by many industries to transform their manufacturing process.

1. Fixed Automation

It is also called hard automation and it has a fixed task. These types of automation are used in large volume production and most programming is contained within the individual machines.

Body-in-white is one of the best examples of fixed automation which is used in automotive.

Advantages:

Low unit cost

High production rate

Disadvantages:

High susceptible to risk

Antiquation

Relatively inflexible in lodging product variety

High commencing investment

2. Programmable Automation

When there are customization & frequent changes throughout the manufacturing process, then programmable automation is the best choice to use.

The whole process is controlled by a program of instruction that is read & interpreted by the system. You can also enter a new program into the hardware to produce new products at any time.

Industrial robots are the best example of programmable automation.

Advantages:

Best suited for batch production

Able to deal with design variation

Disadvantages:

Need high investments

Lower production rate as compared to fixed automation

3. Flexible Automation

To produce a variety of parts, manufacturing companies use flexible automation, with virtually no time lost for changeovers.

This type of automation is connected to some networks and programmers can upload new programs to work them in existing systems from anywhere in the world.

Robots arms that are programmed for multiple tasks are the best example of flexible automation.

Advantages:

Provides medium production rates

Multiple varieties of products can be produced

Disadvantages:

Need high investments

High unit cost than fixed automation

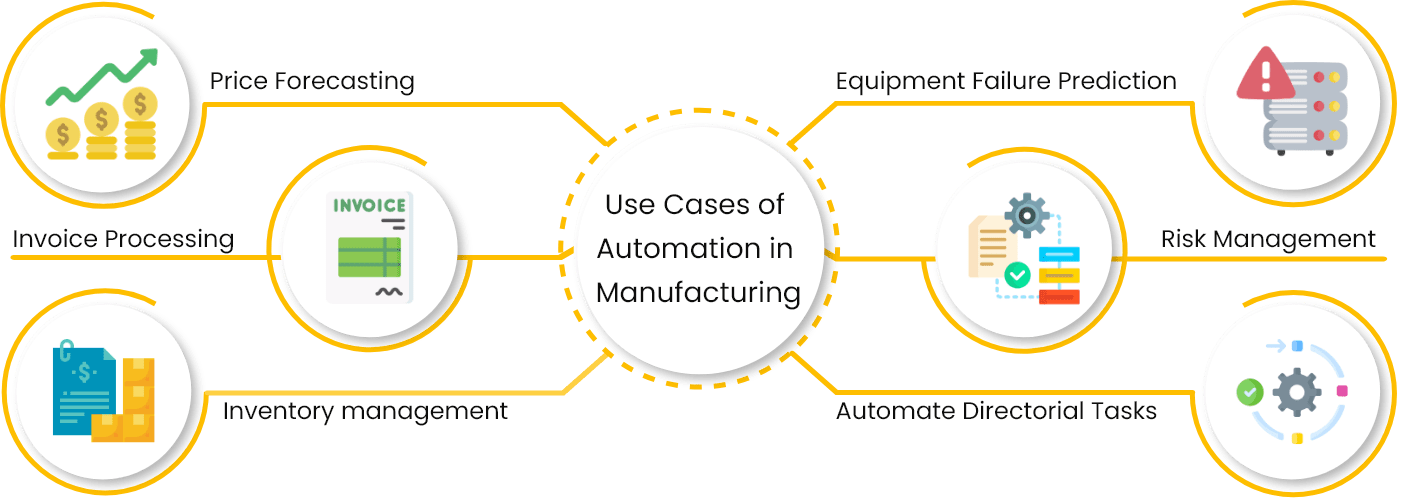

Now let’s see the use cases of automation in manufacturing.

AI in Manufacturing Robots

AI-powered robots in manufacturing are equipped with sensors and algorithms to perform tasks autonomously. They can handle everything from welding and assembly to packaging and quality inspection, improving both speed and precision.

Role of AI in Manufacturing Automation

AI is critical in automating key manufacturing functions. By leveraging data from machines and cameras, AI systems can detect inefficiencies, predict equipment failures, and ensure smooth workflows. Automation also helps reduce human error and downtime, creating a more reliable production process.

Importance of AI in Manufacturing Automation

AI-driven automation brings significant advantages to manufacturing, including increased operational efficiency, reduced waste, and improved product quality. Additionally, AI enhances workplace safety by monitoring worker compliance and detecting potential hazards. Systems like AI ensure workers are wearing necessary protective equipment (PPE) and that factory areas remain secure from unauthorized access.

The main purpose of manufacturing industries is to attain sustained growth & earning through customer loyalty, creating high-value products, and eroded disruption in a very dynamic global market.

First, let’s know the types of manufacturing automation.

Many manufacturing companies are facing several muddles like assembly, test, and packaging tasks. According to research, losses due to these types of manual work have increased close to 30%.

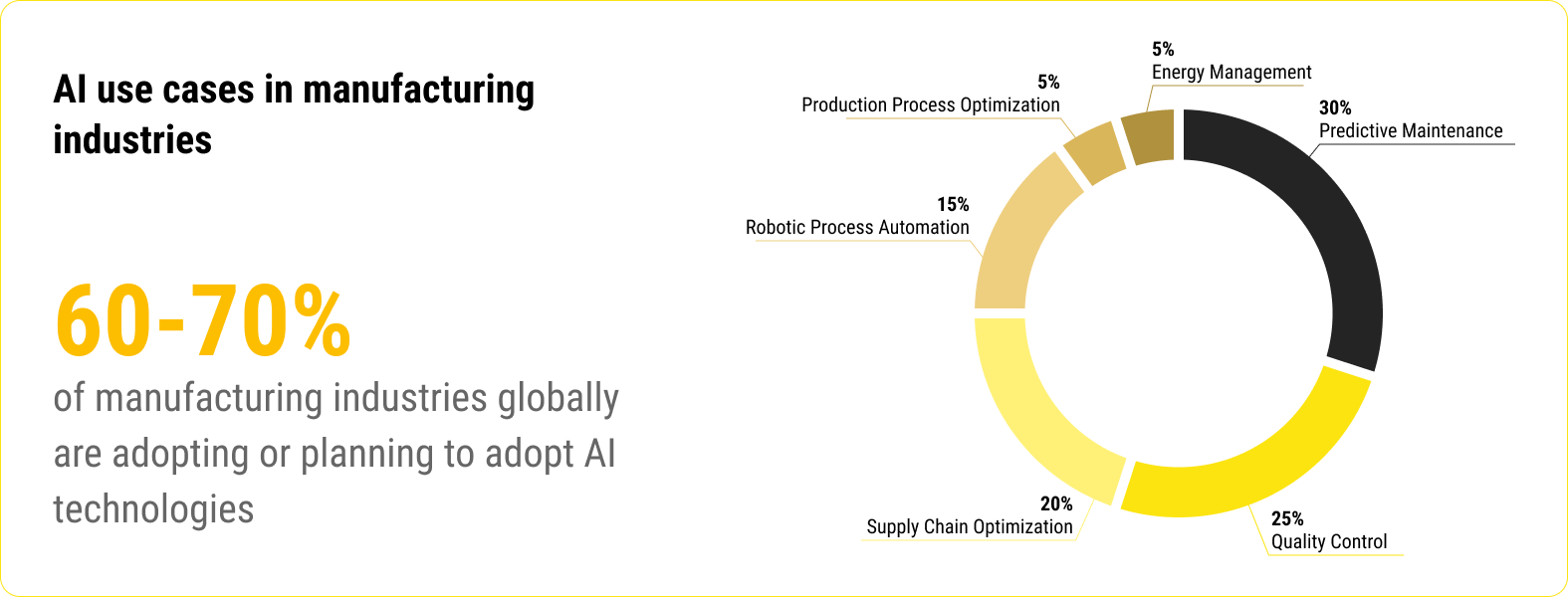

There are lots of use cases of automation that every manufacturing industry needs to leverage for its industrial growth.

Equipment Failure Prediction

Sometimes during the manufacturing process, there could be some product that may look perfect but during its use its performance decreases which may cause equipment failure.

Many companies are facing the same issue, but computer vision has great potential to inspect the performance & quality of equipment to ensure all parts are perfect and there is no chance of equipment failure.

To compete with competitors it is important to transform your manufacturing process using AI solutions which may save you lots of time, money, & extra effort.

Every industry needs to predict its product price accurately, if not done then that may cost huge revenue loss for the company.

There are lots of manufacturing industries that are leveraging the power of machine learning to forecast the price of their products with great accuracy.

Machine learning algorithms have great potential to predict the accurate price of products based on past data.

Accurate price of the product is very essential for any type of company to save a huge amount of money from being lost.

Invoice Processing

When invoice processing is done manually then the task of obtaining, assigning, and approving takes much more extra time which needs to be optimized for every manufacturing company for gaining higher productivity.

Robotic Process Automation is great technology to use for invoice processing. RPA uses the UiPath for automating the invoice processing task with great efficiency without any human intervention.

Many large companies are leveraging the RPA for processing invoices, which may result in revenue growth.

Inventory Management

While doing manual inventory management requires many processes like sending emails, file invoices, and dispatch processes which consumes more time.

To solve the above hitch, manufacturers can use the RPA which can automate important tasks like sending email, digitizing paperwork, filing invoices, and the dispatch process which will definitely save extra time and will improve efficiency.

To increase efficiency, reduce costs, and enhance communication, every manufacturing company needs to integrate the AI into their processing line to see the major growth effect.

Automate Directorial Tasks

Administrative tasks like recording meetings, ordering supplies, recording actions & meeting minutes, and predicting computer problems are all time-consuming and sometimes become overwhelming.

There is many office automation AI software that has great potential to automate all these tasks and finish in time with great efficiency.

Manufacturing companies are facing these hitches and can leverage automation software to automate this tedious task, which creates a critical business impact in the long run.

Risk Management

Many manufacturing companies are facing the issue of risk associated with different tasks in their company, which may result in a negative business impact at any time.

RPA can provide proactive and fully automated audits for business processes. Automated workflows can predict risk and alert stakeholders of hitches that may arise and can be fixed before big damage.

Customer Support

While handling the customers manually it becomes hard to track the information and records which may result in a negative customer experience.

To resolve the above muddle, many manufacturing companies are using the RPA to automate these tasks and to serve a better customer experience.

RPA customer service management is a great AI software that can automate the majority of tasks of customer support.

Read Also:

Product Counting: AI can automatically count products as they move along the production line, ensuring inventory accuracy and preventing discrepancies. This AI system monitors production speed and helps prevent bottlenecks.

Harness Detection: Ensuring worker safety is essential in manufacturing. AI uses computer vision to detect whether workers are wearing safety harnesses in high-risk areas, preventing accidents and ensuring compliance with safety protocols.

Helmet Detection: AI monitors whether workers are wearing helmets in areas where head protection is required. This system enhances safety and reduces the risk of injury, ensuring that manufacturers comply with workplace safety regulations.

People Headcount Detection: AI tracks the number of people in specific areas of the factory, preventing overcrowding and ensuring safe working conditions. This also helps manufacturers optimize labor deployment and monitor workforce efficiency.

Intrusion Detection: By detecting unauthorized access to restricted zones, AI helps maintain security within manufacturing facilities. It alerts security teams in real-time if anyone enters dangerous or off-limits areas, protecting both people and equipment.

Siemens: Siemens incorporates AI for predictive maintenance and real-time equipment monitoring, improving efficiency in production.

BMW: Uses AI for quality inspection, ensuring each vehicle meets stringent quality standards.

General Electric (GE): GE leverages AI to optimize operations in its factories, using AI for predictive analytics, process automation, and improving product design across its industrial platforms.

Foxconn: Foxconn, a leading electronics manufacturer, uses AI to automate its assembly lines and for quality control, helping reduce defects and improve production efficiency in the manufacturing of electronics such as iPhones

Improved Safety: AI systems enhance workplace safety by monitoring worker behavior and ensuring compliance with safety protocols.

Increased Efficiency: AI systems like product counting and people headcount detection optimize workflows, reduce downtime, and minimize production delays.

Cost Savings: With automation of safety monitoring and inventory management, manufacturers reduce human error, lower operational costs, and prevent costly accidents.

A case study involving AI in a manufacturing facility demonstrates how AI can enhance both safety and productivity. By deploying AI systems for helmet detection, harness detection, and intrusion monitoring, the facility saw a 30% reduction in workplace accidents. Furthermore, product counting systems improved inventory accuracy by 25%, reducing losses due to miscounted stock.

Product Counting: AI can automatically count products as they move along the production line, ensuring inventory accuracy and preventing discrepancies. This AI system monitors production speed and helps prevent bottlenecks.

Harness Detection: Ensuring worker safety is essential in manufacturing. AI uses computer vision to detect whether workers are wearing safety harnesses in high-risk areas, preventing accidents and ensuring compliance with safety protocols.

Helmet Detection: AI monitors whether workers are wearing helmets in areas where head protection is required. This system enhances safety and reduces the risk of injury, ensuring that manufacturers comply with workplace safety regulations.

People Headcount Detection: AI tracks the number of people in specific areas of the factory, preventing overcrowding and ensuring safe working conditions. This also helps manufacturers optimize labor deployment and monitor workforce efficiency.

Intrusion Detection: By detecting unauthorized access to restricted zones, AI helps maintain security within manufacturing facilities. It alerts security teams in real-time if anyone enters dangerous or off-limits areas, protecting both people and equipment.

Siemens: Siemens incorporates AI for predictive maintenance and real-time equipment monitoring, improving efficiency in production.

BMW: Uses AI for quality inspection, ensuring each vehicle meets stringent quality standards.

General Electric (GE): GE leverages AI to optimize operations in its factories, using AI for predictive analytics, process automation, and improving product design across its industrial platforms.

Foxconn: Foxconn, a leading electronics manufacturer, uses AI to automate its assembly lines and for quality control, helping reduce defects and improve production efficiency in the manufacturing of electronics such as iPhones.

A case study involving AI in a manufacturing facility demonstrates how AI can enhance both safety and productivity. By deploying AI systems for helmet detection, harness detection, and intrusion monitoring, the facility saw a 30% reduction in workplace accidents. Furthermore, product counting systems improved inventory accuracy by 25%, reducing losses due to miscounted stock.

Improved Safety: AI systems enhance workplace safety by monitoring worker behavior and ensuring compliance with safety protocols.

Increased Efficiency: AI systems like product counting and people headcount detection optimize workflows, reduce downtime, and minimize production delays.

Cost Savings: With automation of safety monitoring and inventory management, manufacturers reduce human error, lower operational costs, and prevent costly accidents.

Most of the manufacturing companies are leveraging automation which has created a major impact on their business growth and has truly competed with their competitors.

To be in the manufacturing market you will have to innovate your manufacturing processes which will transform your business with high ROI.

We build custom AI solutions that completely transform your business and take your business to the next level.

We are happy to help you

As AI continues to advance, the future of manufacturing will be defined by fully automated and connected factories. AI-driven systems like AI will become more sophisticated, providing even greater operational efficiencies, safety enhancements, and predictive capabilities. The integration of AI in every aspect of manufacturing is set to create smart factories that operate with minimal human intervention, improving both productivity and safety.

Q: How does AI works in manufacturing industries?

A: AI systems use data from sensors and cameras to monitor production lines, detect inefficiencies, and ensure safety compliance. These systems can also predict equipment failures and automate workflows.

Q: How has AI evolved in the manufacturing industry?

A: AI has evolved from basic automation tools to advanced systems capable of real-time decision-making, predictive analytics, and ensuring safety and efficiency in factories.

Q: What is the use case of generative AI in manufacturing industries?

A: Generative AI can create virtual prototypes and test designs before physical production, saving time and reducing costs.

Q: How is AI used in car/automobile manufacturing industries?

A: AI is widely used in car/automobile manufacturing for predictive maintenance, quality control, assembly line automation, and supply chain management.

Q: What manufacturing industries are most using AI?

A: AI is prevalent in industries like automotive, electronics, and consumer goods, where precision, efficiency, and safety are critical to maintaining production standards.

Q: Can AI improve product quality and reduce defects in manufacturing industries?

A: Yes, AI-driven systems for quality control can detect product defects in real time, ensuring that only high-quality products leave the factory, reducing waste and improving overall quality.

This website uses cookies to improve your experience. We'll assume you're ok with this, but you can back-out if you wish.