There is a very high demand for the manufacturing industry which in turn calls for brand new requirements, challenges, and security and safety concerns for the workers. The installed CCTV cameras just remotely monitor and track the facility. However, there is a need to automate the alerts in the situation of any safety & security-related issue, so that anything beyond normal and acceptable can be identified in the nick of time, thereby eliminating the need for the concerned person or admin to constantly watch the video footage in real-time.

Here is where our Video Analytics solutions in the Manufacturing Industry come into play. Industrial Video Analytics is revolutionizing many organizations, and the manufacturing industry can be part of this big change.

The manufacturing industry could require quite a few Video Analytics Use Cases, which will serve to ease the processes of this fast-paced, high-demand industry. High turnover rates mean more production, more raw materials, more logistics, and larger inventories. Due to this, video analytics applications have kept increasing too, to have a safer and more productive manufacturing unit, and provide assistance and support to warehouses.

Now that you know why Video analytics is required for monitoring safety and to provide work efficiency, let’s look at how does Video analytics works?

Video analytics is a technology that processes videos coming from cameras and by applying specific algorithms it can perform security and safety-related functions. Some of the most common types of video analytics:

Video analytics determines if any suspicious or unwanted behavior is occurring in the field of view of the camera and the algorithm notifies the operator. These algorithm analytics are fixed and are designed to perform a specific task in a pre-determined manner.

We will now look at some of the advantages & needs of video analytics automation in manufacturing industry, to begin with, there are several manufacturing analytics solutions such as Safety measure detection, unauthorized access management, quality control, and many more.

Safety measure detection: Worker safety is a major concern in every manufacturing plant. Hazardous gases, damaged safety kits, electric damage, and perilous actions are some of the things that need to be monitored and kept under control.

Companies need to ensure that they manage their EHS risks effectively and for this, they can adapt Video Analytics solutions for Manufacturing purposes.

Video analytics could involve the detection of Personal Protective Equipment such as hard hat detection, safety belt detection, face mask detection, glove detection, jacket detection, etc. This equipment can be monitored and alerts can be sent instantly should there be any aberration.

Unauthorized access management: Factory Video Analytics has face recognition that allows only authorized personnel to enter into the restricted premise. This will prevent theft in factories, and any deceitful activities that could take place, as instant alarms can be raised if such practices are identified.

It will only allow the necessary workers to enter their specific rooms, and only allow entry in the given time as alerts can be sent for beyond timeframe ingress.

AI for quality assurance: Video Analytics technology can be applied for ensuring quality and sends an alert notification to the monitoring personnel in case of any damage to equipments. Similarly it can be used for conveyor belt monitoring, level detection of molten metal, detection of spillages, detection of jamming, material quality monitoring, temperature checks, measurement, and color recognition.

Logistics management: This could involve counting the number of boxes, vehicle number plate recognition, type recognition, in-out time, or during loading/offloading. Video Analytics for logistics can also assist commercial drivers and alert them about lanes, the road ahead, or other vehicles at the plant.

Video analytics has become the need of the hour in the manufacturing industry. The rise of automation and technological advancements has made companies more creative, looking for new ways to make their processes more intelligent and efficient.

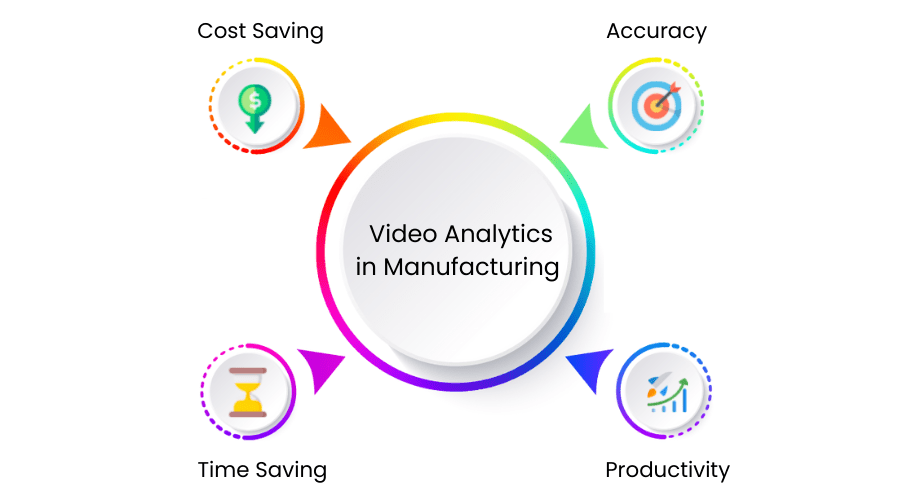

Cost Saving: By using video analytics solutions, many businesses are reducing their cost of operation, thereby saving their money from unnecessary spending. Video surveillance and analytics in warehouses and production facilities are used instead of guards which reduces the overall operation cost.

Time-Saving: Manufacturing real-time video surveillance monitors every corner of the company and quickly spots any movement as compared to other safeguards without taking much time.

Productivity: Many chemical companies automate their process with video analytics to make chemical products so that they can manufacture quality products in less time which increases their productivity.

Risk Reduction: Critical hazards are always present in manufacturing companies hence to monitor this many chemical companies use video analytics solutions to ensure safety with great accuracy & efficiency.

Theft Reduction: Companies use video analytics software to protect their products and equipment from thieves. By using a video analytics solution they can monitor their equipment at all times.

Accuracy: Earlier, when any product was made by hand, the accuracy of that product used to be very low, but since the manufacturing companies are using video analytics software to make their products, the accuracy of their product has increased significantly.

Be it monitoring people, products, or machinery, AI can do it all; right from face recognition for attendance to noting the on/off time of the machine, to measuring dimensions of raw materials to the counting of products, video analytics is here to stay. Video analytics can make surveillance and monitor smarter and more accurate.

Daten & Wissen is the leading AI company that specializes in providing Video Analytics solutions to emerging and large-scale businesses. We are a team of experts who provide only the best solutions within less time.

We are happy to help you

Q: Where is video analytics used?

A: Be it in warehouses, offices, or retail stores, if there is CCTV footage, it can be analyzed. Security, surveillance, equipment monitoring, healthcare, or face recognition can leverage AI and video analytics solutions.

Q: What are common application areas for video analysis?

A: Face recognition, people monitoring, attendance, surveillance or security, equipment monitoring, object detection, measurement, product counting, and logistics management to name a few.

Q: Why do we need video analytics?

A: Video analytics will eliminate the need for keeping track of everything happening on-premises. Video analytics could make it easier for the admin or person of authority to check for aberrations, as they will get notifications or alerts accordingly.

-min.png)

Written by

Daten & Wissen is the team of expert AI engineers to help your business to embark on a transformational journey with the adoption of this futuristic technology.

Many logistics companies have been managing their work just by using pen, phones, and p…Read more

Artificial intelligence (AI) is an emergent branch of Computer Science concerned with a…Read more

Artificial Intelligence is the most advanced technology through which human lives …Read more

This website uses cookies to improve your experience. We'll assume you're ok with this, but you can back-out if you wish.