Manufacturing plants operate in fast-paced, high-risk environments where safety, productivity, and uptime directly affect business performance. With large shop floors, heavy machinery, and multiple shifts, maintaining real-time visibility across manufacturing operations remains a constant challenge.

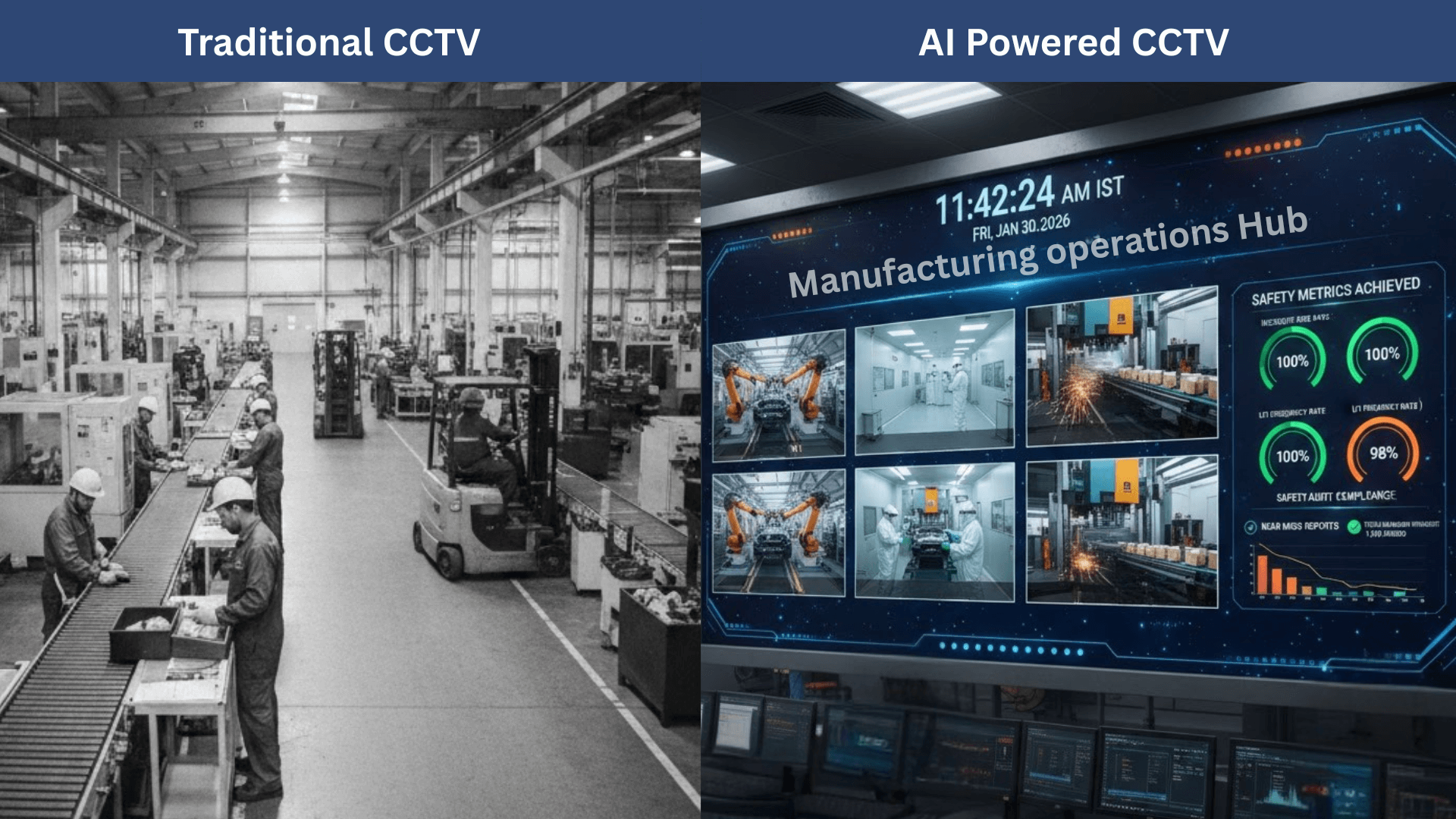

Most manufacturing facilities already rely on CCTV cameras across production lines and restricted zones. However, these systems are largely passive—recording video for review after an incident rather than delivering actionable insight in real time. This lack of continuous oversight has serious consequences, as manufacturing accounts for nearly 20% of global workplace accidents, many linked to delayed detection and unsafe behavior.

Video analytics software transforms industrial cameras into intelligent monitoring systems. By applying AI and computer vision to live video feeds, manufacturers can detect safety violations and operational risks as they occur. Facilities using video analytics have reported 30–40% reductions in safety incidents, enabling a shift from reactive monitoring to proactive, data-driven manufacturing operations.

In this article, we explore how video analytics software is reshaping the way manufacturers use industrial cameras, the key use cases it supports on the factory floor, and the business value it delivers in terms of safety, efficiency, and operational visibility.

Key Takeaways

- Video analytics transforms traditional industrial CCTV cameras into intelligent systems that actively monitor manufacturing operations.

- Manufacturers gain real-time visibility into safety compliance, worker behavior, and operational activities across the factory floor.

- AI-powered video analytics enables proactive risk prevention by detecting unsafe conditions before incidents occur.

- Manufacturing-specific use cases such as PPE detection, fire detection, and vehicle monitoring help reduce accidents and downtime.

- Automated insights reduce dependence on manual monitoring and post-incident video review, improving operational efficiency.

- By leveraging existing camera infrastructure, video analytics delivers measurable ROI with minimal additional investment.

Why Traditional Camera Monitoring Falls Short in Manufacturing

Despite widespread camera deployment, traditional monitoring approaches struggle to meet the demands of modern manufacturing.

Manual monitoring does not scale. A limited number of operators cannot continuously observe dozens or hundreds of camera feeds. This makes it easy for safety violations or inefficiencies to go unnoticed.

Traditional systems are also reactive. Footage is typically reviewed only after an incident has occurred - after an accident, quality issue, or equipment damage. At that point, the cost has already been incurred.

Large manufacturing facilities operate across shifts and departments, making consistent oversight difficult. Patterns such as repeated unsafe behavior or recurring bottlenecks often remain hidden in raw footage.

Without analytics, cameras remain passive tools rather than active contributors to operational improvement.

What Is Video Analytics Software for Manufacturing and Industrial CCTV Cameras?

Video analytics software uses artificial intelligence and computer vision to analyze video streams from industrial CCTVs. Instead of simply recording footage, the software identifies people, objects, movements, and behaviors relevant to manufacturing operations.

For example, video analytics can detect whether workers are wearing proper PPE, identify congestion near production lines, or flag unauthorized entry into restricted zones. These insights are generated automatically, without requiring constant human supervision.

The key difference between traditional surveillance and video analytics lies in interpretation. Traditional systems show what happened. Video analytics explains what is happening and why it matters.

Importantly, video analytics works as a software layer on top of existing CCTV infrastructure. Manufacturers can unlock additional value from their current CCTV investments without replacing hardware.

How Video Analytics Works in a Manufacturing Environment

In a manufacturing environment, video analytics acts as an intelligent software layer that continuously observes activity across the factory floor. It integrates seamlessly into daily operations and works alongside existing systems without disrupting production.

Industrial cameras installed across production lines, warehouses, loading areas, and restricted zones stream live video throughout the plant. This footage is analyzed by video analytics software in real time, ensuring critical events are detected as they happen.

The system uses AI models trained on manufacturing-specific scenarios. These models recognize people, machinery, vehicles, and movement patterns, enabling detection of safety violations, abnormal behavior, congestion, and deviations from standard operating procedures.

When defined conditions are met, the system generates alerts and insights through dashboards and reports. Instead of monitoring camera feeds, safety and operations teams receive clear, actionable intelligence that enables faster response, risk prevention, and improved operational efficiency.

Manufacturing-Specific Use Cases

Video analytics delivers the most value when applied to real manufacturing challenges. Some of the most common use cases include:

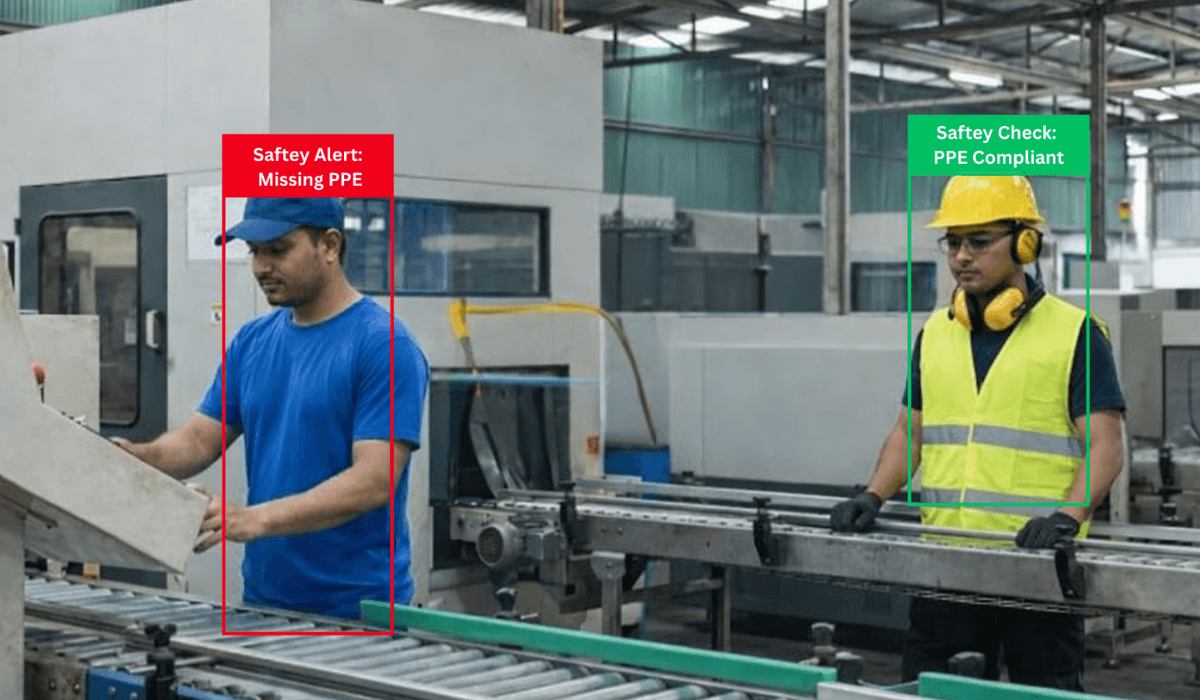

1) PPE Detection

Automatically detects missing helmets, vests, gloves, or face masks in hazardous zones to enforce safety compliance in real time. This ensures continuous monitoring across shifts in high-risk areas such as production lines, welding zones, and machinery sections, reducing workplace injuries and improving audit readiness.

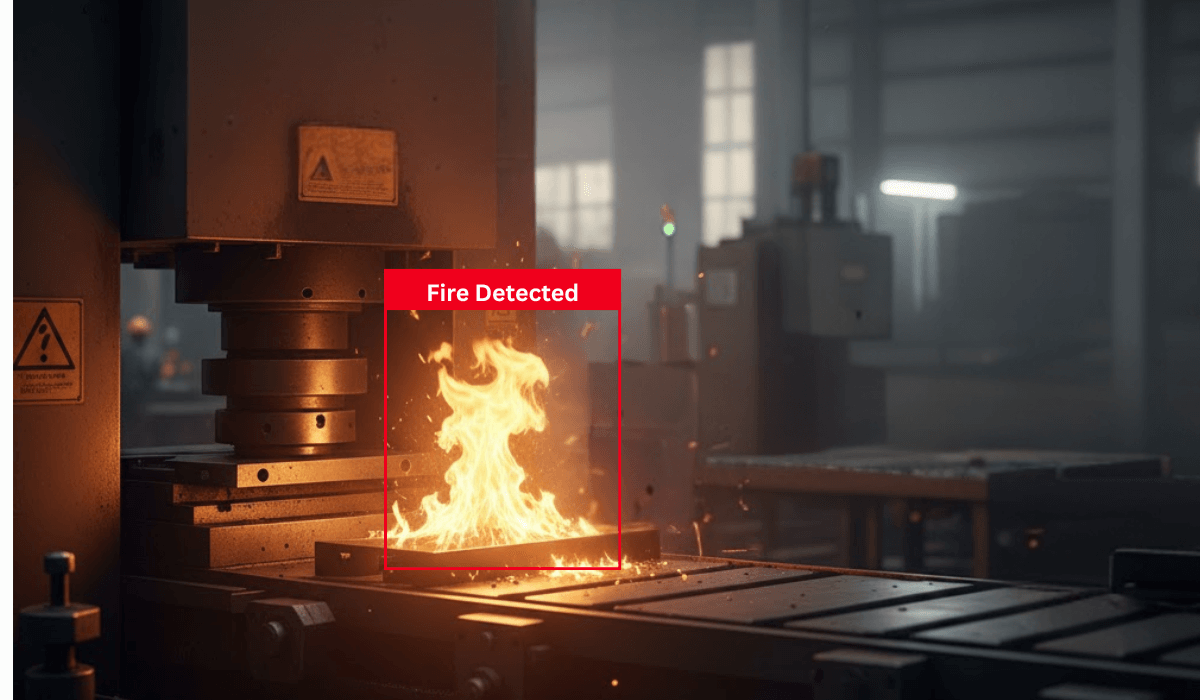

2) Fire & Smoke Detection

Identifies early signs of fire or smoke visually—often before traditional sensors trigger alarms—enabling faster response. In manufacturing environments with electrical equipment, furnaces, or flammable materials, early detection helps prevent equipment damage, production loss, and safety incidents.

3) Entry–Exit Detection

Tracks personnel movement through designated access points to ensure only authorized access to sensitive areas. This improves safety and security in zones such as control rooms, chemical storage areas, and high-value production sections within large manufacturing facilities.

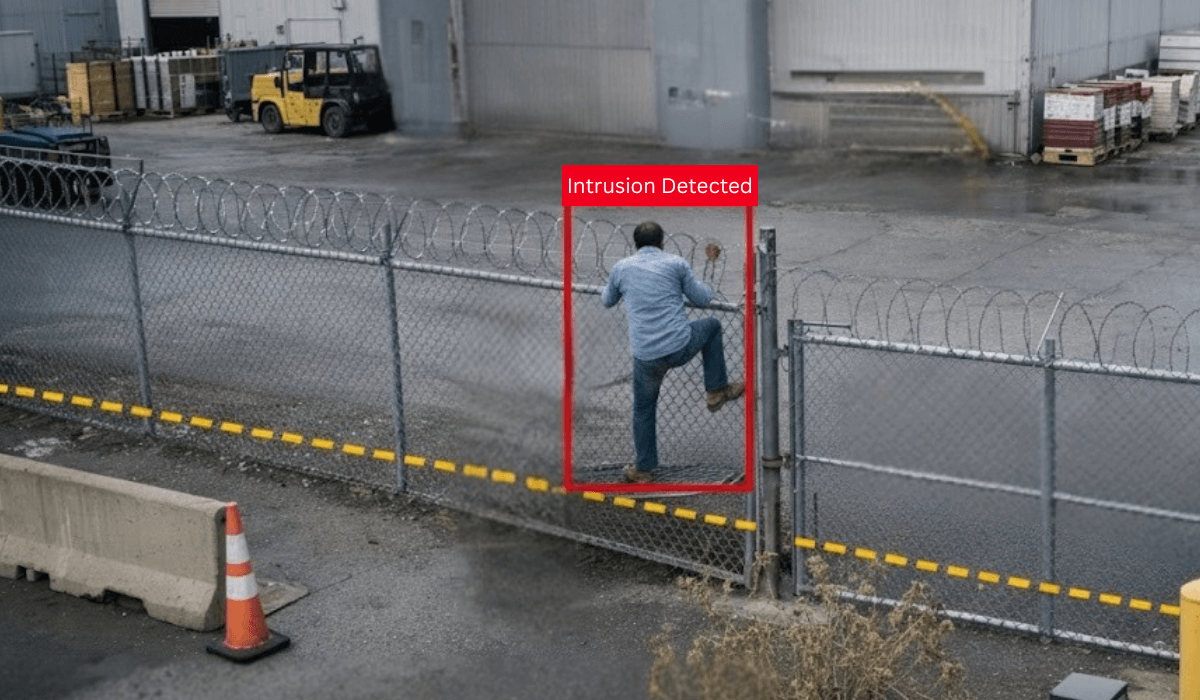

4) Intrusion Detection

Monitors restricted or high-risk zones during operations or off-hours and alerts teams to unauthorized presence. This helps protect critical assets and prevents accidental or unauthorized entry into dangerous areas, especially when physical supervision is limited.

5) Product Counting

Counts items on conveyors and packaging lines in real time, improving production accuracy and reducing manual errors. Real-time counting supports better output tracking, early detection of discrepancies, and improved planning across high-volume manufacturing lines.

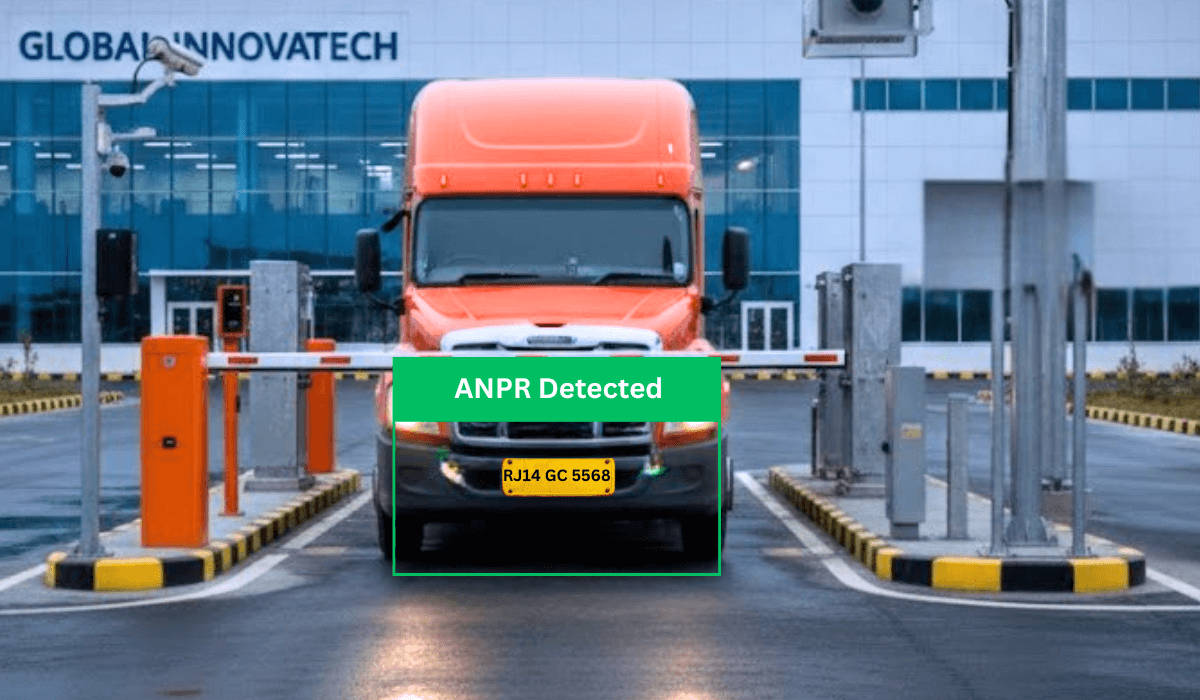

5) ANPR (Automatic Number Plate Recognition)

Tracks vehicle entry, exit, and movement across factory gates and yards for logistics visibility and access control. This enables smoother gate operations, reduced congestion, and better monitoring of supplier, dispatch, and employee vehicles.

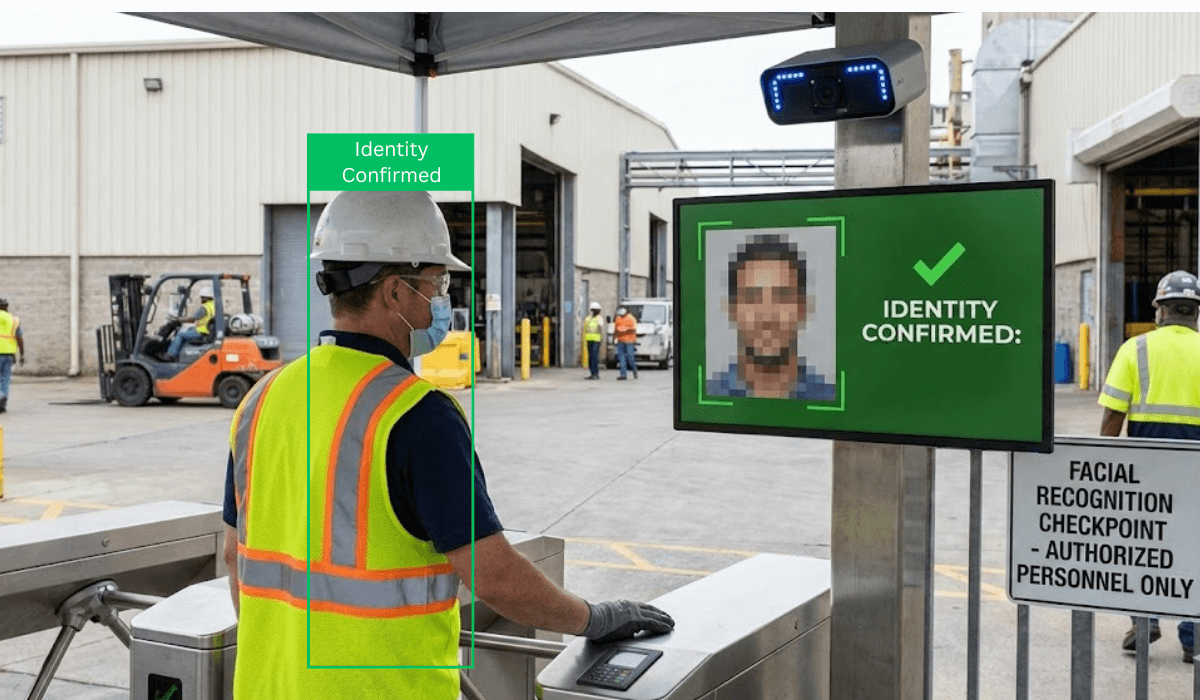

6) Facial Recognition

Supports identity verification for secure zones, shift validation, and controlled access to critical areas. This ensures accountability and secure access in facilities with multiple entry points and large workforces without disrupting daily operations.

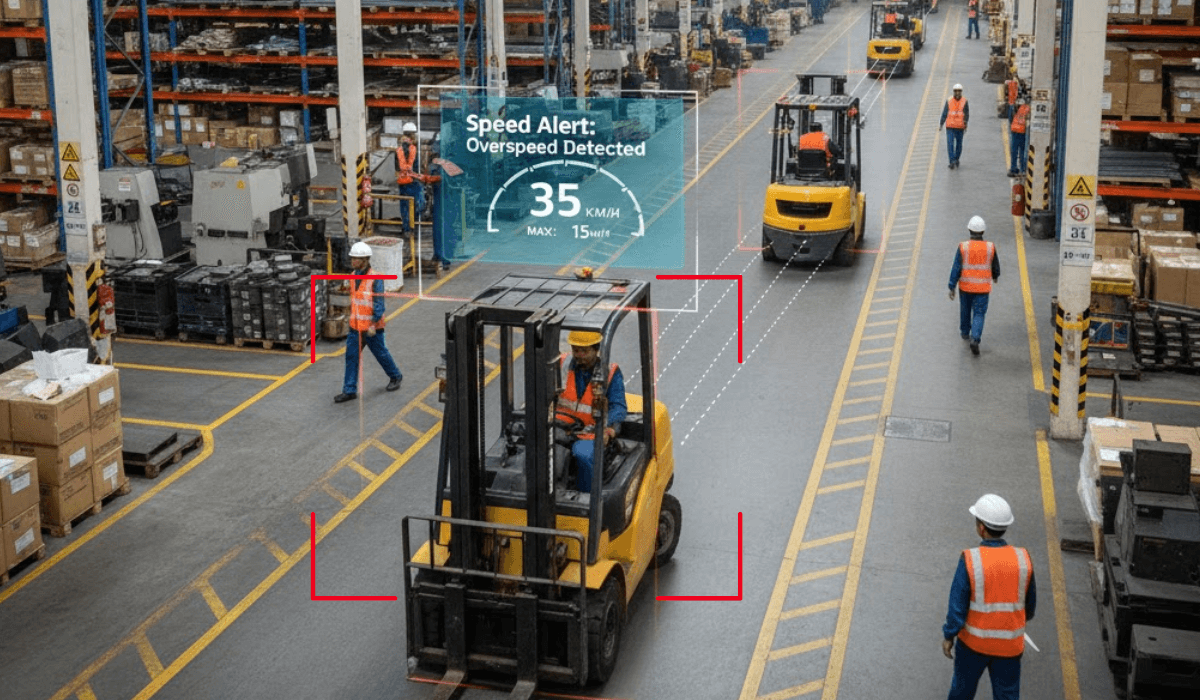

7) Overspeed Detection

Monitors forklifts and industrial vehicles to detect overspeeding in shop floors and warehouses, reducing collision risk. Enforcing safe speed limits helps protect workers, equipment, and materials in shared movement areas.

AI-driven video analytics can reduce incident detection time by over 50%, enabling faster intervention and safer operations.

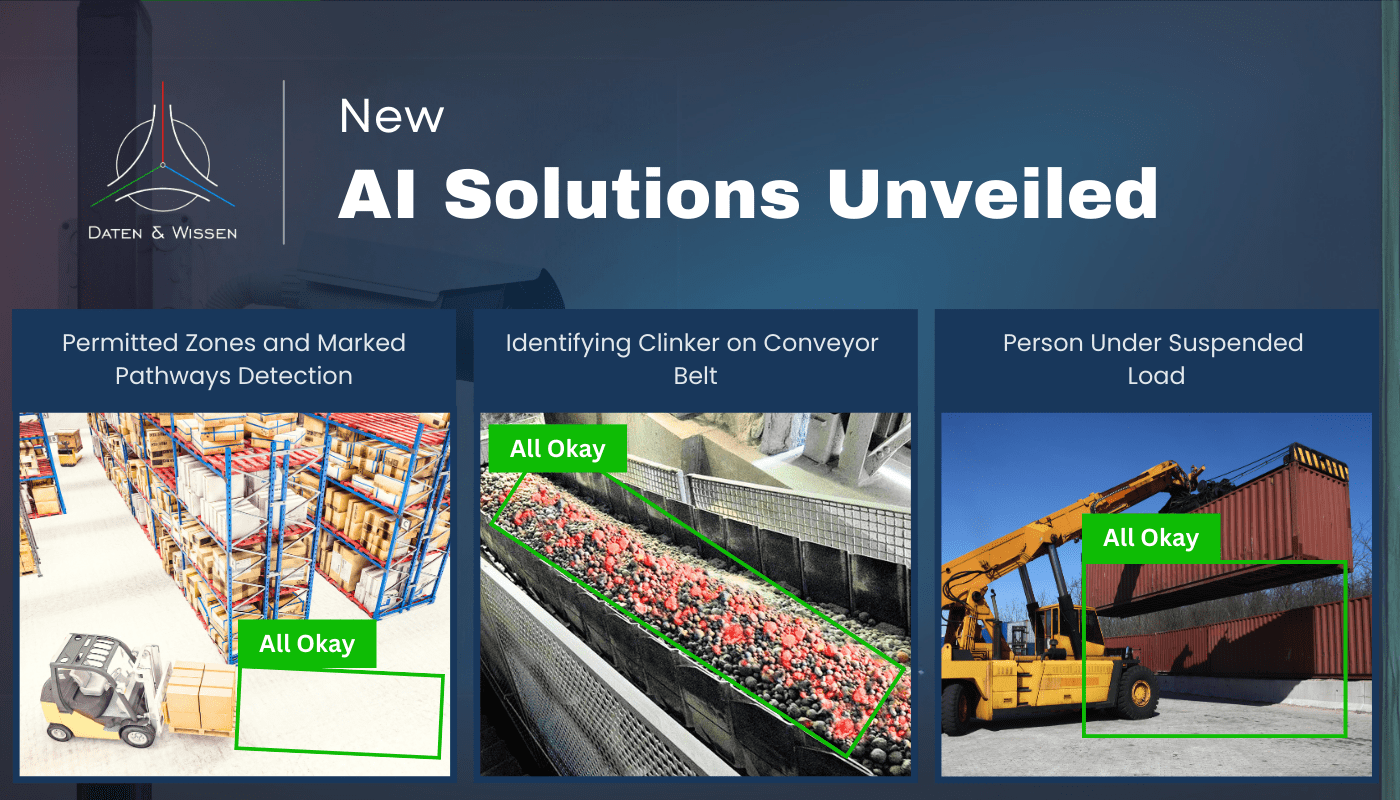

Read also: New AI-Powered Safety Solutions to Keep Your Workplace Secure

Smarter, Safer Factories with NWarch AI Video Intelligence

NWarch AI converts a plant’s existing CCTV network into a proactive manufacturing intelligence system that detects risks, enforces procedures, and drives operational improvement in real time. Deployed as a lightweight software layer at the edge or on-premises servers, NWarch ingests live video from production lines, yards, and restricted zones and applies manufacturing-trained computer vision models to spot PPE non-compliance, unsafe proximity, fire and smoke indicators, equipment anomalies, congestion, product-counting discrepancies, overspeeding forklifts, and unauthorized entry.

Because it integrates with existing cameras, deployment avoids rip-and-replace costs; edge inference minimizes latency and bandwidth while preserving data privacy. Detected events are automatically tagged, prioritized, and routed through zero-code automation workflows — sending mobile alerts to safety officers, triggering audible warnings on the floor, creating maintenance tickets, or pushing summarized incidents to dashboards and MES and SCADA integrations. NWarch also provides natural-language AI agents for on-demand queries and fast root-cause searches, so managers can ask plain-English questions like “show last week’s PPE exceptions on Line 3” and receive filtered clips and analytics.

The platform’s customizable rules and scalable, multi-site architecture support centralized reporting, consistent policy enforcement, and role-based access controls for auditability and compliance. By converting passive video into prioritized, actionable intelligence, NWarch reduces incident detection time, lowers manual monitoring effort, accelerates investigations, and helps maintain compliance — delivering measurable ROI through fewer safety events, reduced downtime, and improved throughput.

In short, NWarch turns ordinary CCTV cameras into an intelligent, integrated layer of operational control that keeps people safer, production steadier, and leaders better informed. Deployments typically complete within weeks, not months, and on-site fine-tuning combined with continuous model learning from plant footage improves detection accuracy over time; dedicated support and analytics services ensure the solution evolves with changing processes and yields sustained operational benefits, and measurable KPIs track value continuously across operations consistently.

ROI of Video Analytics for Safety in Manufacturing

Return on investment is a key consideration for manufacturing leaders evaluating safety and operations technologies. Video analytics delivers ROI by reducing both direct costs from incidents and indirect losses caused by operational disruption.

Safety incidents often result in medical expenses, compensation claims, equipment damage, and regulatory penalties. Beyond these visible costs, accidents also cause unplanned downtime, production delays, and productivity loss that directly affect plant performance.

By detecting risks early, video analytics helps prevent incidents before they escalate. Continuous monitoring of PPE compliance, restricted zones, and unsafe behavior enables faster intervention and reduces the frequency and severity of safety events.

Video analytics also lowers the effort spent on manual monitoring and post-incident investigations. Automated detection, event tagging, and faster root-cause analysis reduce downtime and stabilize operations, translating into predictable costs and measurable long-term value.

Business Benefits for Manufacturing Leaders

Beyond ROI, video analytics strengthens safety culture by actively monitoring risks. When employees see unsafe conditions detected and addressed in real time, they are more likely to follow procedures, reducing accidents and building trust on the shop floor.

It also gives leaders clearer operational visibility. Teams can see real patterns in how work is performed, identify inefficiencies, and focus improvement efforts where they matter most, without relying solely on manual checks or reports.

For multi-plant operations, video analytics ensures consistent application of safety and operational standards. By leveraging existing camera infrastructure, manufacturers gain actionable insights, support scalable growth, and improve operational control with minimal additional investment.

Video Analytics System Requirements for Manufacturing

Factories present demanding conditions, so video analytics solutions must be designed specifically for industrial environments. They should perform reliably in low or uneven lighting, dusty areas, and around heavy machinery, while maintaining high accuracy to detect operational issues or safety risks early.

Speed is critical. For safety and operational scenarios, the system must analyze video and generate alerts in real time or near real time. Delayed insights reduce the ability to intervene and increase risk.

Scalability is also essential. Whether monitoring a single plant or multiple facilities, the platform should support a growing number of cameras and users without adding complexity or compromising performance.

Finally, the system must meet enterprise security standards and be easy to deploy and manage. Features like clear access controls, secure data handling, and simple configuration help ensure the solution is trusted, adopted, and sustainable over the long term.

The Future of Video Analytics in Manufacturing

As manufacturing continues to advance through digital transformation, video analytics is becoming a core component of modern factory operations rather than just a standalone safety tool. Its role is expanding beyond monitoring to actively supporting operational decision-making.

The focus is shifting toward predictive intelligence. Video analytics will increasingly identify early warning signs—such as unsafe behavior, process deviations, or equipment anomalies—before they disrupt production or cause accidents.

Video insights will also integrate more closely with automation systems and operational data, helping manufacturers improve process efficiency, reduce variability, and drive continuous improvement across the shop floor.

As these technologies mature, deployment and scaling will become simpler, making advanced intelligence accessible across more areas of the plant. Manufacturers that adopt intelligent video early will be better positioned to enhance safety, optimize operations, and build more resilient, data-driven production environments.

Conclusion: Turning Industrial CCTVs into Manufacturing Intelligence

Industrial CCTV cameras are already a standard part of most manufacturing facilities. However, without analytics, they largely serve as passive recording tools, used only after an incident has occurred. This leaves a significant amount of potential value untapped.

Video analytics software changes this by turning existing CCTVs into intelligent systems that actively support safety and operations. By analyzing live video and highlighting risks, inefficiencies, and abnormal behavior, manufacturers can move from reactive monitoring to proactive decision-making. This shift helps reduce workplace incidents, minimize downtime, and improve overall operational control.

For manufacturing leaders focused on long-term performance, resilience, and continuous improvement, video analytics is more than a technology upgrade. It is a strategic investment that transforms everyday visual data into actionable manufacturing intelligence—supporting safer, more efficient, and more informed operations across the factory floor.

FAQs

How does video analytics help reduce workplace accidents?

By detecting unsafe conditions and behaviors in real time, video analytics enables faster intervention before incidents escalate.

Is video analytics suitable for multi-site manufacturing operations?

Yes. Platforms can scale across multiple facilities and provide centralized dashboards for consistent monitoring.

What ROI can manufacturers expect from video analytics?

ROI comes from fewer incidents, reduced downtime, faster investigations, and better utilization of existing cameras.

Does video analytics replace safety teams?

No. It enhances human decision-making by providing timely insights, allowing teams to focus on prevention rather than constant monitoring.

Can video analytics improve production efficiency as well as safety?

Yes. In addition to safety monitoring, video analytics supports product counting, congestion detection, and workflow optimization to enhance overall operational efficiency.