Chemical industries are one of the most important industries for other sectors because industries from pharmaceutical to automotive depend on the chemical industry so it becomes more important for the chemical industry to be more productive by maintaining the quality of their chemical products.

The chemical plant managers have a responsibility to ensure that quality chemicals are being produced and for this purpose, the chemical plant should be maintained properly.

Predictive Analytics in the chemical industry is a great technology that can be harnessed in order to cut costs, reduce downtime, & ensure safety measures, etc.

In this article, you will learn how chemical industries can leverage the power of predictive analytics in order to produce high-quality chemicals with less investment.

Many chemical industries have begun to integrate predictive analytics in their core system to ensure better quality chemical production with more safety precautions.

Predictive analytics has many capabilities like demand forecasting, sentiment analysis, root cause analysis, predictive modeling, predictive maintenance, and predictive monitoring which can transform the overall chemical industry to report maximum growth.

Let's assume that you want to forecast the conditions of equipment so that you can repair them early rather than replacing them. For this purpose, you can use predictive maintenance to analyze the data & forecast the maintenance condition of the equipment with better accuracy.

Let's see what are the use cases of predictive analytics in the chemical industry?

Creating a high-quality chemical product requires a large amount of budget but predictive analytics has the ability to cut off the major extra costs which may lower your budget.

While creating a high-quality chemical product you should be aware of the demand of that product and for this, you can harness predictive analytics to forecast the demand of the product so that you will be able to optimize your budget.

When some parts of the machinery get damaged then it needs to be replaced which may increase your cost but predictive maintenance can predict the condition of parts in a very early stage so you can repair them which may extend equipment lifespan.

When you create the product then its major success depends on the quality of the product & if the quality has been compromised then there would be product recall which may result in huge revenue loss.

You can use predictive monitoring & predictive maintenance technology in the chemical industry to detect the anomalies of the plant & pick them early enough to prevent them significantly affecting product quality therefore you can produce the high-quality product with great accuracy & efficiency.

The chemical industry is full of different types of chemicals and if it is not handled properly then it may cause a big problem for your employees, environment & other equipment.

You can use predictive maintenance software to reduce the manual checking process of the chemicals. Predictive maintenance can detect the spillages, flares, leakages, and other types of incidents that may be hazardous for the environment & the workers.

Many chemical companies have started to use predictive maintenance software to reduce the risk of chemical accidents & ensure safety precautions.

When any component faces downtime then it may cost a huge amount for the company. Many companies are still using manual methods to check the downtime of important equipment which increases the inspection time.

Predictive maintenance has the potential to check the condition of the components before they stop working so you can cease the downtime of the component which may save you extra money & time.

Predictive maintenance has the capability to improve the performance & efficiency of every piece of equipment. You can use value maximization modeling to interact between pieces of equipment across processes.

Many chemical companies are harnessing advanced analytics that shows how to maximize the rate of profit generation in complex production systems and supply chains.

You just cannot simply deploy the solution to get the full performance potential of the entire chemical production process. You will have to make changes on people, technology fronts, and processes to make sure that they get most of the findings.

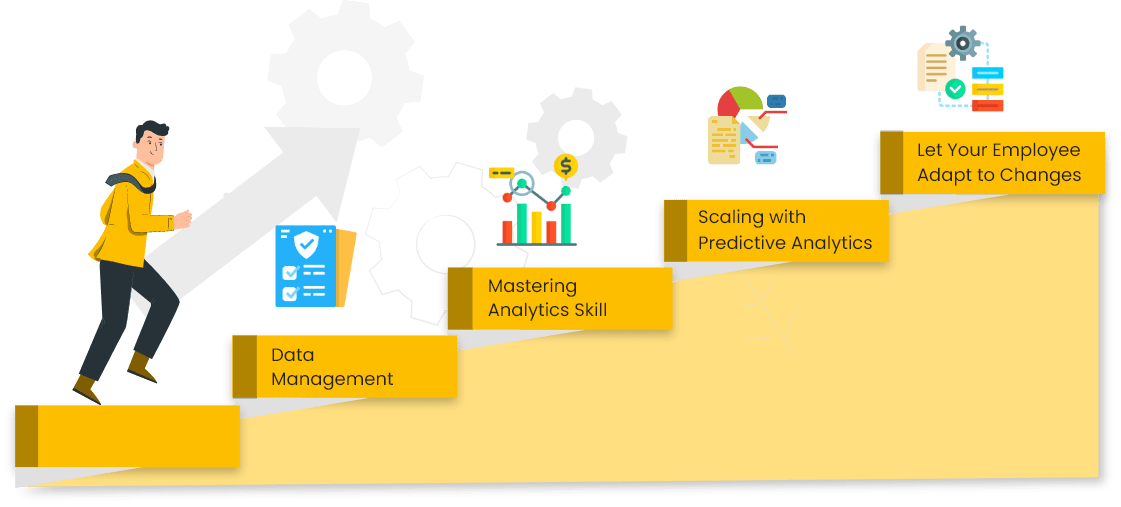

You can use the following step to transform your chemical production process by achieving better accuracy & efficiency.

While using advanced analytics you will need to retrieve & clean the data and structure it properly according to the platform you will use.

You will have to aggregate the data from different types of sensors in different locations and need to store the information on various platforms. For these tasks, you will need some IT experts who have experience in the field of AI & data analytics.

It is important to master advanced analytics skills in order to process the data with better accuracy & efficiency. To ensure that the development of the model is accurate you will have to make a team of data analysts, data scientists, and manufacturing experts.

Creating the accurate predictive maintenance & predictive analytics model requires deep knowledge of data analytics skills.

Once you have an expert team with knowledge of different domains then it is time to scale your chemical production process to the next level.

You will have to take analytics & manufacturing expertise in the same lab with their operational units and by prioritizing the processes you can start the scaling operation.

You will have to train your employees about how their analytics tool can assist them so that they can make their jobs more rewarding.

Employees' mindset is one of the most important factors for successful analytics-enabled transformation for the chemical industry.

Once you have set all the steps then your chemical manufacturing process could be much faster with better performance & accuracy.

Read also:

Predictive analytics is not the game of just a one-time deployment process but it requires continuous deployment to achieve better results with less time.

From top leaders to managers their mindset should be adaptable to changes in order to take the business ahead of the competition. Most of the chemical companies have already deployed the predictive analytics solution in their core business system to get the maximum result.

It is the era where every business will need AI transformation in order to survive & engage their customers hence you should definitely adopt it earlier than your competitors.

We are experts at creating customized AI solutions from the bottom of our hearts. We are constantly updating ourselves in order to attain sharpness of accuracy.

We are happy to help you.

A: There are numerous industries like Chemical, Healthcare, Banking, Fragrance, FMCG, Pharmaceutical, Education, etc. that use predictive analytics in their core system.

A: Predictive analytics are used to promote cross-selling opportunities and track customer purchasing behavior.

A: The primary aspects of predictive analytics are as follows:

1) Deep Learning

2) Machine Learning

3) Automation

4) Data Sourcing

5) Data Utility

This website uses cookies to improve your experience. We'll assume you're ok with this, but you can back-out if you wish.