Food manufacturers across the world are facing numerous hurdles due to the overwhelming global pandemic. During these challenging times, food manufacturers and other organizations that operate in the food sector must take necessary precautions regarding the safety of employees and the quality of food produced.

Video Analytics has been used for preventing theft and contamination in a food production unit. It can even optimize food manufacturing plants’ safety and productivity and send real-time data on the given dashboard.

If you want to get ahead of the competition and make your food manufacturing business more efficient, you need to incorporate a Video Analytics solution. Now, let’s see some of the advantages of video analytics in food production & manufacturing.

Video Analytics uses special algorithms to improve the accuracy and efficiency of the Food Manufacturing Industry, and therefore it can be integrated with the monitoring systems to get intelligence reports and real-time data & alerts on the dashboard.

Below given are some of the advantages of video analytics in food production:

According to some studies, the average loss of a food company is around $10M. Video Analytics is a practical tool that food manufacturers can use to prevent the loss, and monitor production, and manufacturing in real-time on a dashboard.

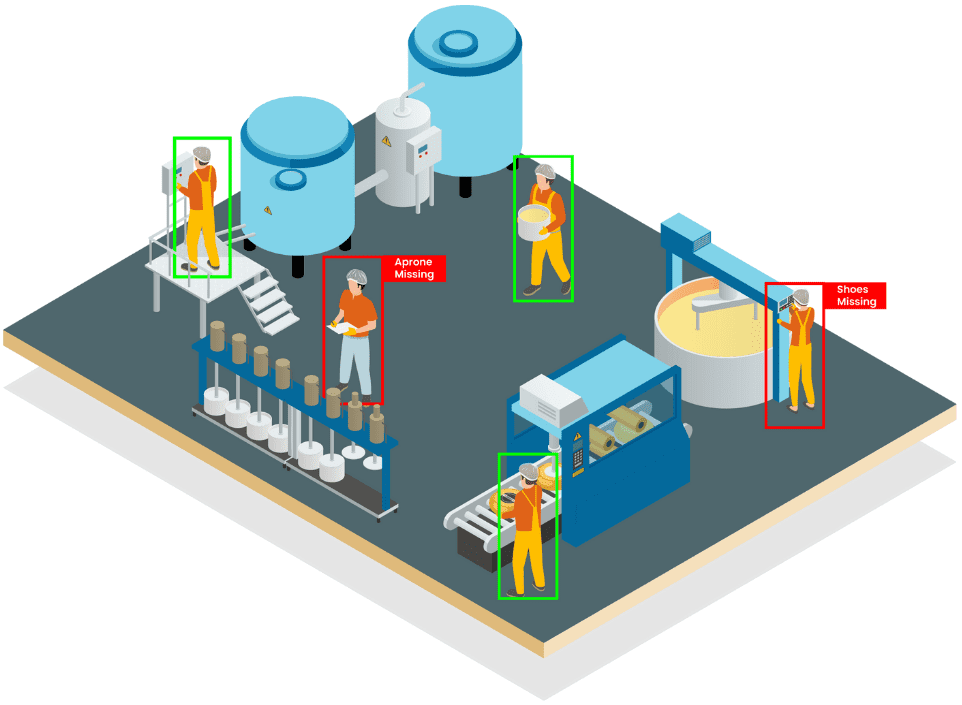

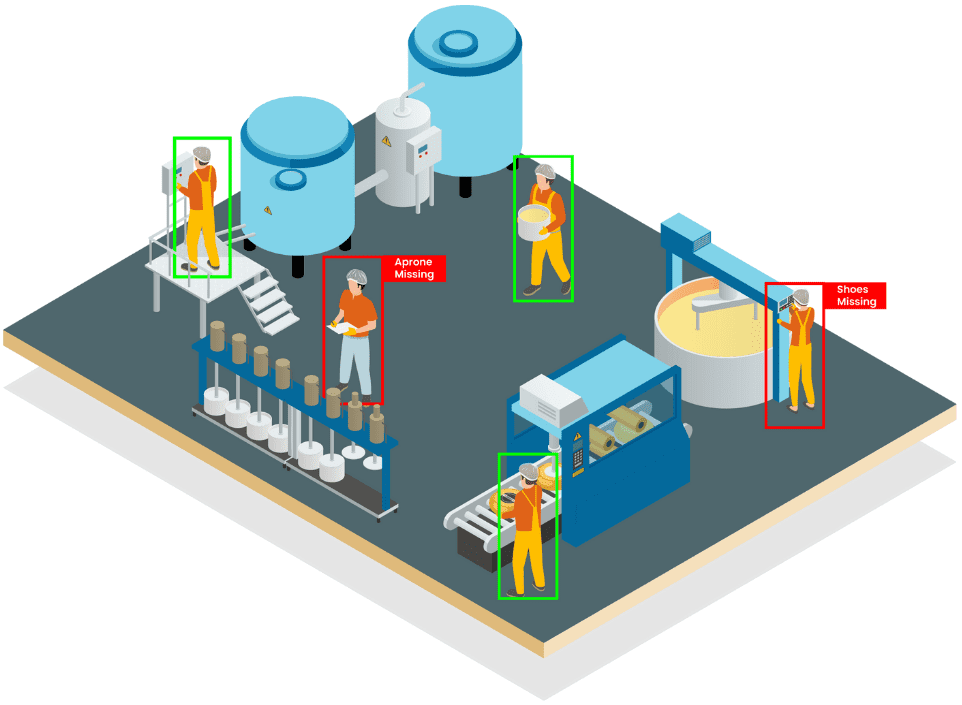

Food manufacturers can check employees’ hygiene and safety using Video Analytics. If safety regulations are violated by the employees, then real-time alerts will be sent to higher authorities and similarly shown on the given dashboard. Video Analytics can be used to check the materials that are used in food manufacturing.

Video Analytics uses advanced Computer Vision and can detect faulty machinery in the facility. If it detects any machine malfunctioning then it sends alerts on the given dashboard. 24/7 monitoring of the whole plant and sending real-time alerts to the higher authorities are some of the essential features of Video Analytics.

With the emergence of the global pandemic, many businesses have taken important steps to meet global safety guidelines. Video Analytics helps manufacturers maintain proper safety and security awareness among the employees.

Video Analytics is used to supervise plant activities and search for any outsiders or trespassers into the factory. If the solution detects any intruder then it sends real-time alerts to the higher authorities and similarly, alerts are sent on the dashboard.

Video Analytics can be used to enhance the visibility of the production and perform quality checks of the food produced. It is used to remotely monitor the health status of the food produced inside the factories and sends the collected data on the dashboard.

Food manufacturers are finding ways to leverage surveillance systems for reducing the amount of loss. Many Food manufacturers make use of advanced Video Analytics for the same purpose. Video Analytics has become increasingly important for understanding the causes of food losses.

Video Analytics solution takes the existing video footage and studies it a perform exception-based analysis. This can be beneficial for food producers and manufacturers as they can monitor organized crime activity such as product sweeping and stealing food product boxes from the factory.

The solution uses cross-line detection and motion detection for checking if any employee is leaving the facility with any food product. It checks for the quality and health of the food product that is being used for production. If it finds any food product as faulty or damaged then it sends a real-time notification to the dashboard.

It is a challenge for manufacturers to manage regulatory compliance and document essential activities even before the pandemic struck because of the complexity of the sector. Video Analytics helps manufacturers by making sure that only authorized people had access to the plant.

Video Analytics monitors and documents important operational activities that are being carried out throughout the plant and shows the data on the given dashboard. It helps ensure that compliance and guidelines are being followed in a food manufacturing plant which in turn increases revenue and introduces much more efficiency to the business.

Food production businesses must cooperate with regulatory organizations such as the Food Safety and Standards Authority of India. The FSSAI has the authority to investigate foodborne illnesses and investigate them.

With largely expanding locations and extremely long supply chains in the food industry, the risk of disease outbreaks and product recalls has severely increased. Video Analytics can assist food production companies with FSSAI investigations.

Video Analytics provides essential applications for compliance with FSSAI regulations. It can help secure toxic chemicals from getting into the food processing machinery, as it constantly monitors the facility and sends instant alerts on the dashboard and to the authorities.

Read Also:

In today’s times, Food Production businesses can use modern technologies to improve their facility’s safety & security. Video Analytics help facilities adapt to a new safety-first environment. Even when the pandemic gets over, manufacturers will continue to supervise the health and safety initiatives with the help of Video Analytics.

To get the Video Analytics solution into your system, you would require a team of experts who specialize in AI-based Video Analytics technology. At Daten & Wissen, you will get all of the above and much more, which would suffice your technological needs.

This website uses cookies to improve your experience. We'll assume you're ok with this, but you can back-out if you wish.