Process optimization is an essential aspect of any Manufacturing environment. The processes are typically designed to produce the highest quality products at the lowest cost. However, the Manufacturing process can vary wildly from one company to another. In addition, the Manufacturing process can be highly complex, with multiple sub-processes and inputs.

The goal of Manufacturing Process Optimization is to find a combination of process parameters that optimizes the product quality and the manufacturing cost. There are many ways to model the process, from simple discrete models to complex continuous models. Machine Learning algorithms are used to improve the accuracy of the optimization models. Similarly, it can be used to predict the performance of the process, predict the optimal combination of process parameters, and predict future process behavior.

Let’s know in the below-given article, how to use machine learning for manufacturing process & production optimization.

Manufacturing industries are improving their production efficiency by adopting the method of Industrial Process Optimization. So, Process Optimization can be defined as the continuous improvement of processes, production, and provision of services of a particular business.

Process or production optimization techniques help improve the overall functioning of the workplace, especially in areas that include machinery, quality monitoring, scheduling maintenance, and many more. In the manufacturing industry, the demand for process optimization is ever-increasing as it produces greater output at a higher quality and requires a low amount of input resources, which is usually time and labor.

Process optimization is all about simplifying workflows by cutting out unnecessary or repetitive steps. The real magic happens when you automate these tasks, making everything run smoother and faster.

Here are some manufacturing process optimization examples:

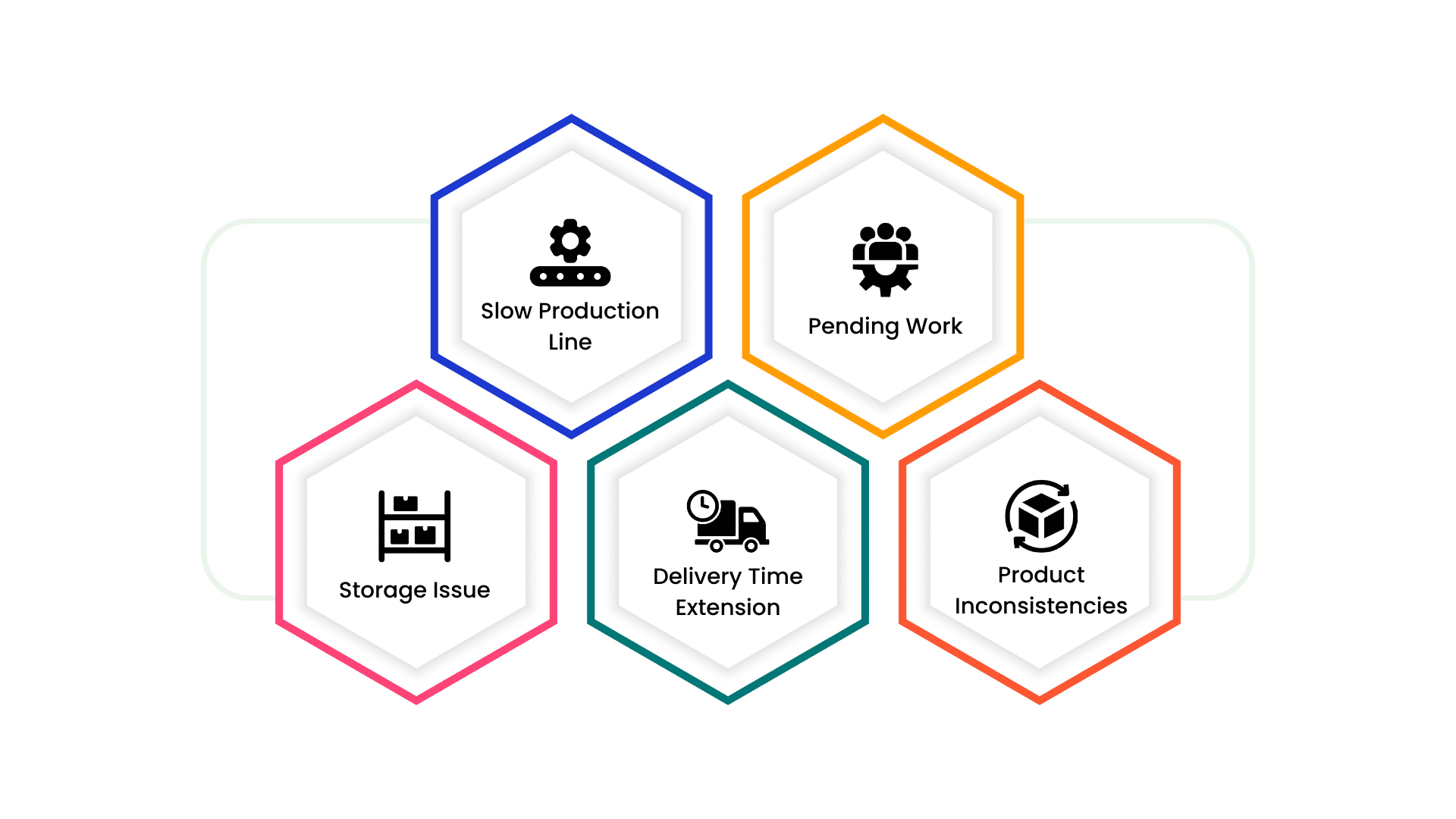

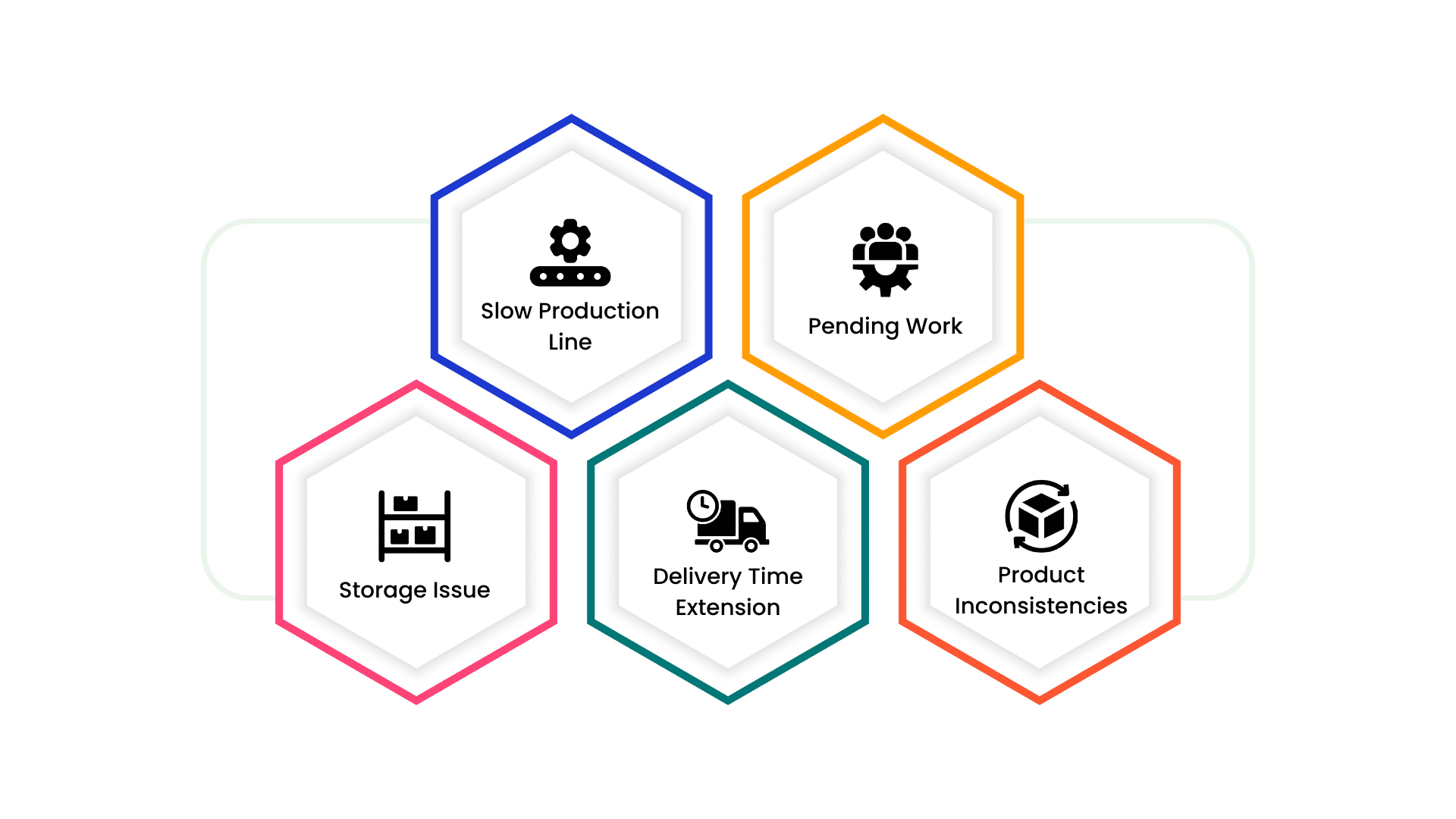

There are innumerable issues and problems related to manufacturing processes which can be seen in the below-given pointers:

With Process Optimization, Manufacturers can optimize their processes for increased production and faster deliveries. Process Optimization also helps monitor employees’ performance thus eliminating wastage of time and increasing efficiency of the workplace. It can also help reduce the time of production, improve the capacity of production, and check for product quality.

Some prominent factors regarding Process Optimization in Manufacturing:

Manufacturing Process Optimization based on Machine Learning techniques has revolutionized the way modern manufacturing organizations function. Conventionally, Operators and Supervisors performed optimizations based on their research and experience, which takes ample time and familiarity with the problem statements. Now, this time-consuming process can be further simplified using machine learning and advanced production optimization techniques

The Machine Learning model intakes and analyzes vast amounts of historical data from platform sensors and learns to understand the relations between various parameters and their effect on production. It can understand like a human operator but unlike humans, Machine Learning algorithms have no issues analyzing fully-fledged historical data for all the existing sensors in the factory. It can even increase the efficiency and accuracy of daily operations and processes in a Manufacturing plant.

Machine Learning algorithms run on real-time data and provide recommendations to the operators on actions that need to be taken for process improvement. These recommendations are identified by the algorithm using given set points and from historical and even live streams.

Machine Learning technology can serve as a support tool for operators to control the processes while helping them make informed decisions for maximizing the performance of the manufacturing processes. These algorithms are capable of predicting the production rate based on adjustable control parameters.

Now, let’s explore what are the optimization techniques in machine learning for process optimization.

1. Prediction algorithm: A predictive algorithm is used to spot issues at an early stage and record the dataset of errors for management. The prerequisite for a Predictive Application model is to have enough data. The more variables, the better it is to predict the problems in the manufacturing process.

2. Multi-dimensional optimization: A prediction algorithm can be used as the foundation of process optimization as it adjusts control variables to maximize production.

3. Actionable output: Optimal outputs can be achieved by Machine Learning algorithms as it recommends which control variables to adjust and it can drastically improve the production rate.

4. Forecast Market Trends: Machine Learning Algorithms have an additional feature of forecasting the market. The algorithm makes use of historical data and predicts the market trends thus increasing future sales.

5. Managing Inventory: Inventory management is the key to optimizing manufacturing processes. Although, It can’t be achieved manually and needs to be automated. Automating the inventory management system will help manage resources more efficiently. Machine Learning algorithms can also forecast inventory requirements.

6. Fault Identification: Machine Learning algorithms collect historical data and anticipate possible problems and issues within the processes. With the help of Machine Learning algorithms, a business will be able to analyze its processes in-depth and find ways to reduce any potential issues in operations.

Process Optimization can enhance manufacturing operations and make processes much more efficient. There are many benefits of applying optimization to the Manufacturing process as given below:

Read More:

By applying machine learning for manufacturing process optimization, plants can achieve more efficient processes and increased quality of products, thereby helping Manufacturers maintain their competitive edge. Machine Learning is an advanced technology as it is used to predict the performance of manufacturing systems.

It can improve the efficiency of production processes by simulating different operating scenarios and adjusting the control parameters. It also enables one to save money and time and at the same time get desirable outcomes. Machine learning and AI can deliver many unseen benefits through process optimization to a manufacturing plant.

We at Daten & Wissen are committed to providing only the best AI solutions to our clients. These solutions are customized to leverage businesses and make them more efficient and cost-effective. If you are swindling through your daily processes and want assistance with automating the manufacturing process then connect with us and tell us your problems.

We would be happy to help you…

This website uses cookies to improve your experience. We'll assume you're ok with this, but you can back-out if you wish.